Welcome to Filsilpek Solutions

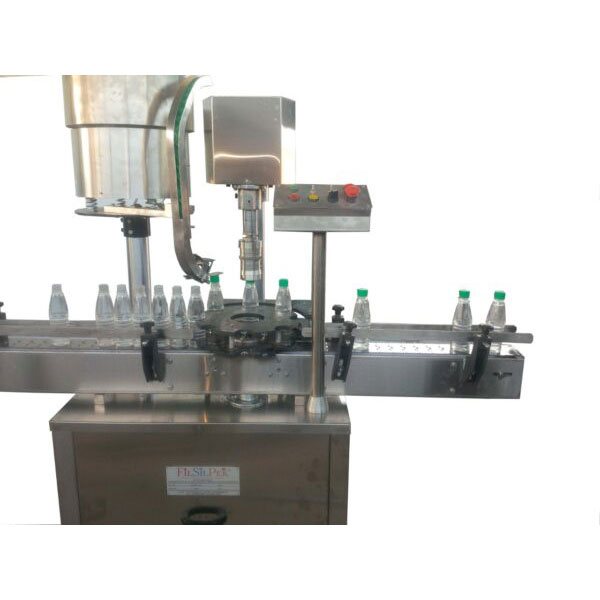

We would like to introduce our company FILSILPEK Solutions Pvt. Ltd Ahmadabad (India), as leading We are a prominent Manufacturer and Supplier of premium quality of Liquid Filling Machine,Viscous Filling Machine,Sealing And Capping Machine,Labelling Machine,Tube Filling Machine, etc.

11 Year’s Experience

We have started our journey in 2013 and we are on the verge of completing our successful 11th year. During this journey we worked with many clients and we are proud that we helped them to achieve their goal with our services.We believe in treating you with the respect we give our co-workers, as a partner in solving your packing challenges. We believe in curiosity,self-improvement,honesty communicationand collaboration.

90+

Types of Machinery

15+

Serving Country

1500+

Installation

1500+

Clients

Industries We Serve

Edible Oil

Lubricant Oil

Syrup Packing

Pesticides Packing

Powder Packing

Paint Packing

Milk,Juice & Honey Packing

Cosmetic Packing

Feature Products

Our Clients

Our Blog

How do automatic oil-filling machines help reduce adulteration and contamination risks in edible oils?

Edible oil manufacturing operates…..

What Floor Space is Needed for an Automatic Oil Filling Machine Setup?

When planning to add an automatic oil filling machine…..

How is an Automatic Oil Filling Machine Installed on a Production Line?

Installing an automatic oil filling machine is more than just…..