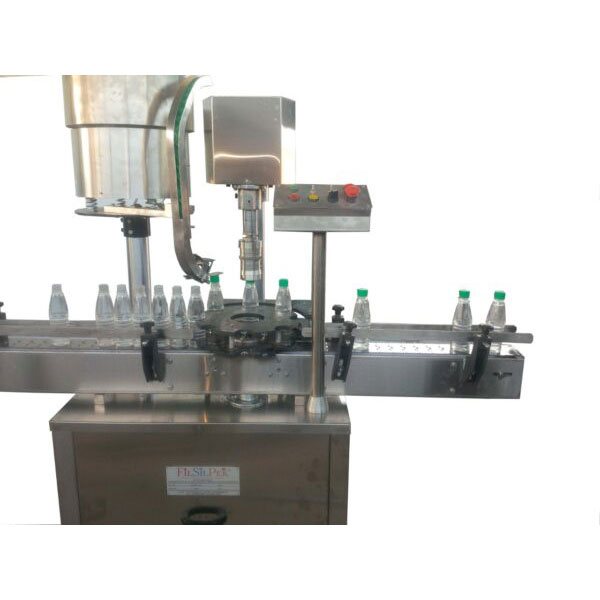

Automatic Inner and Outer Capping Machine

The Automatic inner and outer Capping Machine is precision built on sturdy welded MS frame completely enclose in stainless steel sheet and doors are providing to facilitate the servicing of machine.

Application of Automatic Inner and Outer Capping Machine

- For Agriculture product.

- Pharmaceuticals.

- Oil industry.

Features of Automatic Inner and Outer Capping Machine

- No container No cap arrangement.

- SS elegantly matt finished body.

- Single motor synchronizes conveyor, star wheel.

- Adjustable height of conveyor belt, to align with other machine of the line.

- Sealing pressure can be varied to suit different gauges and size of caps.

- Low noise level, low power consumptions.

- Self-lubricating UHMW-PE guide profile for low friction wears surface, smooth and noiseless conveying.

- SS cladding or hard chrome plating of all exposed parts to ensure long life and resistance against corrosion.

- Synchronized A/C drives to synchronize, Conveyor, Star wheel and Platform turret & capping bow.

Specification of Automatic Inner and Outer Capping Machine

- Output/Hour :- 1000 to 3000**.

- Capping Head :- For inner and Outer cap.

- Direction of Movement :- Left to Right.

- Main Motor:- 1 HP / 415 Volts / 50 Hz.

Filsilpek’s two head mechanical filling solution offers unmatched balance between cost-efficiency and performance

Automatic Pesticides Filling, Capping Machine

Automatic Inner Cap Pressing and Outer Screw Capping Machine upto 5 liter