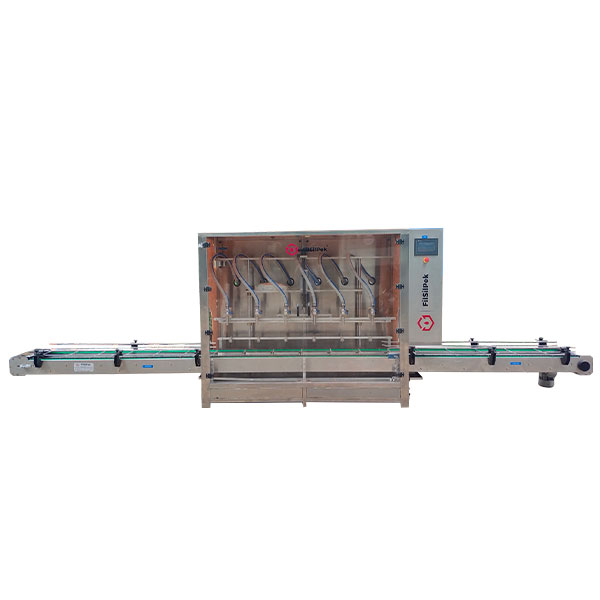

Automatic Weigh Filling Machine

The Electronic PLC Based Filling Machine is compact and highly efficient machine with elegant look. This multi functional multi featured machine meets the GMP requirements of filling for glass, plastic or Aluminum bottles. The flow of liquid is measured and converted in to electronic signals being controlled by micro computer base circuitry. The entire range can be set on the same machine without any change parts with help of Loadcell measurement.

Filsilpek’s Automatic Solvent Base Paint Filling Machine ensures accurate, drip-free fills while maintaining safety and speed for volatile liquids

Application of Automatic Weigh Filling Machine

- Paint

Features of Automatic Weigh Filling Machine

- No Bottle No Filling System.

- All Contact Parts made of S.S.316/S.S.304.

- 4 Filling Stations, space saving design.

- Easy to clean.

- Pneumatically controlled nozzles, with ‘No Container No Fill’ arrangement.

- Drip free nozzle arrangement.

- Reciprocating filling nozzle with self-centering device.

- Pneumatically operated bottle stopper.

Specification of Automatic Weigh Filling Machine

- Filling Range :-500Ml to 4 Liter.

- Output :- 720-750 per hour.

- Filling Operation:- By Load cell base weighing system.

- PLC:- Panasonic/Schneider Make.

- Nozzle controlling:-Actuator through.

- Push Buttons :- Tele Mechanical make.

- Pneumatic Solenoid Valves :- Janatics make.

- Direction of Movement :- Left to Right.

Automatic Paint Filling Solvent Base Machine