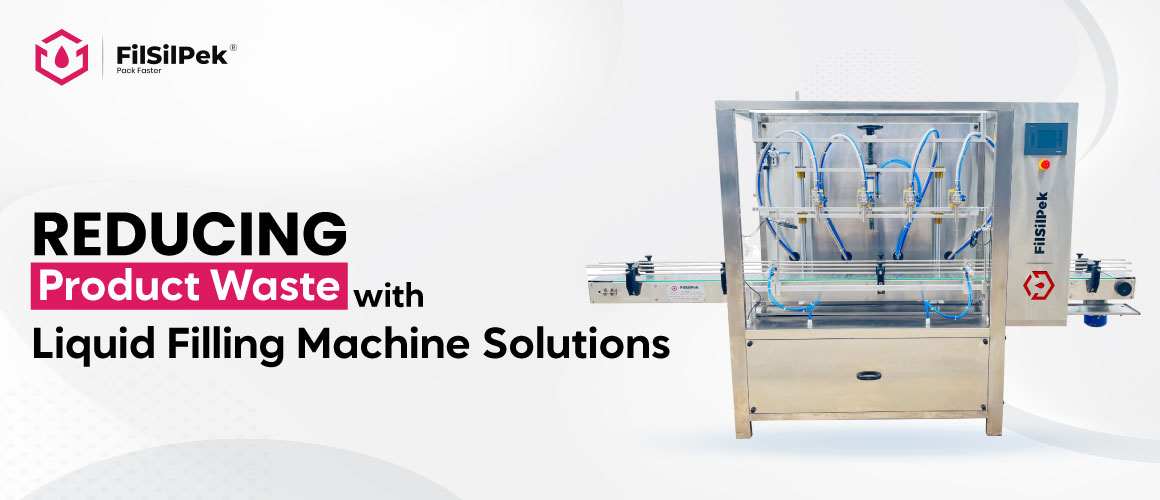

Reducing Product Waste with Liquid Filling Machine Solutions

In the world of manufacturing, efficiency is paramount. Every drop of product wasted equates to lost revenue and environmental impact. Product waste is a major concern for liquid manufacturers, with consequences extending beyond financial losses. However, there’s a shining solution on the horizon: Liquid Filling Machines.

In this article, we will explore how these advanced machines can effectively tackle product waste and revolutionize liquid manufacturing.

Understanding Product Waste: A Major Problem in Liquid Manufacturers

In the highly competitive landscape of liquid manufacturing, minimizing product waste is not just a goal; it’s an imperative. The efficient utilization of resources and the reduction of waste have become central objectives for businesses striving for sustainability and profitability. To tackle this challenge effectively, it’s essential to comprehend the underlying causes of product waste.

Common Causes of Product Waste

1. Inefficient Cleaning Processes

“Residue from previous runs contaminates fresh batches, leading to disposal.”

Inefficient cleaning processes, such as inadequate equipment cleaning or insufficient sanitation procedures, can result in residue from previous production runs lingering within the machinery. This residue, if not thoroughly removed, can contaminate subsequent batches, rendering them unusable and necessitating their disposal. This is a significant source of product waste in the liquid manufacturing industry, as it not only results in lost products but also increases the risk of cross-contamination, which can have serious health and safety implications.

2. Overproduction

“Producing more than what’s required often results in unsold products that go to waste.”

Overproduction is a widespread issue in manufacturing, and the liquid industry is no exception. The desire to meet anticipated demand or to take advantage of economies of scale can lead to the production of excessive quantities of liquid products. When these products cannot be sold or have a limited shelf life, they become wasted resources. Overproduction not only incurs the cost of raw materials, labor, and energy but also leads to storage challenges and eventual disposal costs.

3. Inaccurate Filling

“Even a small variation in filling quantities can result in significant waste over time.”

Accurate filling is paramount in liquid manufacturing, where precise volumes must be dispensed into containers. Any deviation, no matter how slight, from the specified fill level can result in product waste. Inaccurate filling may lead to both overfilling and underfilling. Overfilling not only wastes products but can also cause packaging issues, while underfilling results in customers receiving less than they paid for, potentially damaging a brand’s reputation. Over time, these inaccuracies accumulate, leading to substantial waste and financial losses.

Major Threats Due to Product Waste

Understanding the causes of product waste is essential, but it’s equally crucial to recognize the severe consequences and threats it poses to liquid manufacturers.

1. Financial Losses

“Wasted product directly impacts the bottom line, eating into profits.”

Product waste translates directly into financial losses. Every gallon or liter of liquid product that is discarded represents not only a waste of raw materials and labor but also lost revenue. In a competitive market, where profit margins can be slim, even minor reductions in product waste can significantly enhance a company’s profitability. Managing waste effectively is not just an environmental concern but a financial imperative.

2. Environmental Impact

“Disposing of excess products can have severe environmental repercussions, including pollution and resource depletion.”

The environmental impact of product waste cannot be underestimated. The disposal of liquid products often involves processes that contribute to pollution and resource depletion. For instance, incinerating or landfilling liquid waste can release harmful chemicals and greenhouse gases into the atmosphere, contributing to air pollution and climate change. Additionally, improper disposal practices can contaminate groundwater and soil, further harming the environment.

3. Reputation Damage

“A track record of product waste can harm a company’s reputation and consumer trust.”

In today’s interconnected world, news of environmental negligence or wasteful practices spreads quickly. Companies that consistently waste products may face significant damage to their reputation, which can be challenging to recover from. Consumer trust is hard-earned and easily eroded, and a reputation tarnished by a perception of waste and inefficiency can lead to decreased customer loyalty and reduced market share.

How Liquid Filling Machines Help to Reduce Product Waste?

Now, let’s delve into seven unique ways that liquid filling machines can effectively reduce product waste:

1. Anti-Drip Technology

Modern liquid filling machines are equipped with anti-drip technology. This means that the filling nozzles are designed to prevent dripping after the filling process is complete. By minimizing drips and spillage, these machines reduce product waste significantly.

2. Automatic Container Adjustment

Liquid filling machines can automatically adjust to different container sizes and shapes. This adaptability ensures that there is minimal excess space in the container, reducing the need for overfilling and minimizing waste.

3. Real-time Monitoring and Adjustment

Advanced liquid filling machines are often equipped with sensors and monitoring systems. These systems continuously check and adjust the filling process in real time. If any inconsistencies or deviations are detected, adjustments are made immediately, ensuring precise filling and minimal waste.

4. Ingredient Traceability

Many liquid filling machines come with sophisticated ingredient traceability features. This means that every ingredient used in the filling process is meticulously tracked and recorded. In case of any quality or contamination issues, it’s easier to identify and recall affected products, reducing waste and potential harm.

5. Reduced Changeover Times

Quick changeover between different products or container sizes is a hallmark of modern liquid filling machines. This reduces the downtime between batches, enabling manufacturers to produce smaller quantities without sacrificing efficiency. Consequently, this leads to less overproduction and waste.

6. Smart Inventory Management

Some liquid filling machines are integrated with inventory management systems. These systems help manufacturers keep a tight grip on their raw materials and finished product inventory. By avoiding overstocking and monitoring shelf life, manufacturers can minimize waste associated with expired products.

7. No Bottle No Filling Technology

Liquid filling machines equipped with “No Bottle No Filling” technology ensure that the filling process only occurs when a container is present. This intelligent feature prevents spills and waste by halting the filling process when there’s no bottle in place. It’s a fail-safe mechanism that guarantees efficient use of products and minimizes waste.

Conclusion

The battle against product waste in liquid manufacturing can be won with the help of advanced liquid filling machines. By addressing common causes of waste, adopting anti-drip technology, automating container adjustment, ensuring real-time monitoring, enhancing ingredient traceability, reducing changeover times, and implementing smart inventory management, manufacturers can significantly cut down on waste.

These machines are not just precision tools; they are the vanguards of efficiency and sustainability in the modern manufacturing landscape. Embracing liquid filling machine solutions is not only a business-savvy choice but also an environmentally responsible one.

How can automatic powder filling technology streamline packaging of powdered biofertilizers in sustainable agriculture?

The demand for biofertilizers has increased sharply as agriculture moves toward….

What new challenges arise in packaging high-value cosmetic oils extracted from food-grade raw materials, and how do filling machines adapt?

High-value cosmetic oils like argan, almond, jojoba, avocado….

How are D2C edible oil startups using smart filling systems to offer personalized packaging for home delivery?

Direct-to-consumer (D2C) edible oil brands are changing the way households buy and use cooking oils. By cutting….