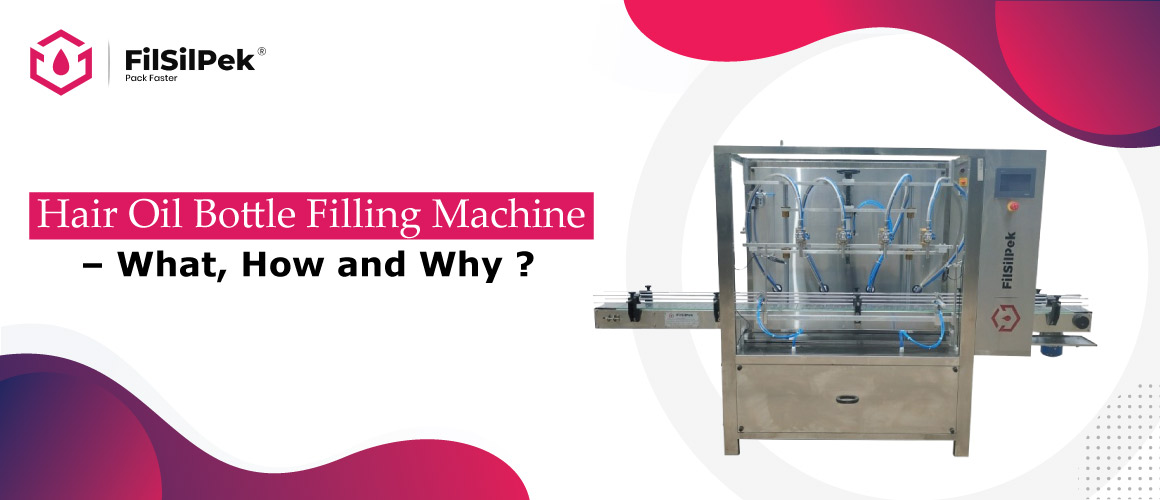

Hair Oil Bottle Filling machine – What, How and Why ?

In manufacturing and production era, technology continues to play a pivotal role in enhancing efficiency and precision. One such innovation that has revolutionized the cosmetic and personal care industry is the Hair Oil Bottle Filling Machine. This cutting-edge equipment has streamlined the process of filling hair oil bottles, offering numerous benefits to manufacturers and consumers alike.

In this article, we are going to discuss, what, how and why about this ultimate machine.

What is a Hair Oil Bottle Filling Machine?

A Hair Oil Bottle Filling Machine is an automated device designed to accurately dispense and fill hair oil into bottles. This equipment eliminates the need for manual labor in the filling process, ensuring consistency, speed, and hygiene. Typically equipped with advanced technology, these machines are capable of handling various bottle sizes and types, making them adaptable to different production needs.

How Does a Hair Oil Bottle Filling Machine Work? A Step-by-Step Guide

Bottle Placement

- Empty bottles are placed on a conveyor belt or a designated filling area.

- Bottles are arranged for smooth movement through the machine.

Bottle Orientation

- Optical sensors or mechanical systems ensure correct bottle positioning.

- Verification that bottles are properly aligned for the filling process.

Filling Station Setup

- The machine is programmed with the required volume of hair oil for each bottle.

- Multiple filling stations may be set up for different bottle sizes or product variations.

Filling Process

- As bottles move along the conveyor belt, pumps or nozzles dispense precise amounts of hair oil.

- Sensors monitor the process, ensuring accurate volume dispensing into each bottle.

Drip Prevention

- Mechanisms are in place to prevent excess product from lingering on the bottle exterior.

- Ensures cleanliness and prevents product wastage.

Bottle Sealing

- Bottles move to the sealing station immediately after filling.

- Caps, lids, or other sealing methods are applied to securely contain the hair oil.

Quality Control and Inspection

- Cameras or sensors inspect each filled and sealed bottle for defects.

- Only products meeting quality standards proceed to the next stage.

Labeling and Packaging (Optional)

- Integrated systems apply labels to bottles that pass quality control.

- Bottles are then packaged for distribution, depending on the machine’s capabilities.

Conveyor Exit

- Filled, sealed, and labeled bottles exit the machine via the conveyor belt.

- Bottles are now ready for distribution or additional processing.

Why Invest in a Hair Oil Bottle Filling Machine? Exploring Unique Advantages

While the decision to invest in a Hair Oil Bottle Filling Machine is undoubtedly a strategic one, the unique advantages it offers go beyond basic efficiency and precision. Here are some distinctive reasons why manufacturers in the cosmetic and personal care industry should consider incorporating this technology into their production processes:

Customization Capabilities:

Hair Oil Bottle Filling Machines can be tailored to accommodate a wide range of bottle shapes, sizes, and materials. This customization capability is particularly valuable for manufacturers producing diverse product lines with varying packaging requirements.

Enhanced Safety Measures:

Precision in dispensing ensures that the exact amount of hair oil is filled into each bottle, minimizing product wastage. This not only contributes to cost savings but also aligns with sustainability goals by reducing the environmental impact of manufacturing processes.

Enhanced Safety Measures:

The adaptability of these machines extends beyond handling different bottle types. They can also efficiently fill bottles with various hair oil formulations, whether the product is a thick serum, lightweight oil, or a specialized treatment. This versatility is crucial for manufacturers with diverse product portfolios.

Enhanced Safety Measures:

Hair Oil Bottle Filling Machines often come equipped with advanced safety features, such as emergency stop buttons and sensors that detect abnormalities in the filling process. These measures contribute to a safer working environment for production personnel.

Quick Changeover and Setup:

Manufacturers frequently face the challenge of transitioning between product runs swiftly. Hair Oil Bottle Filling Machines are designed for quick changeovers and setup adjustments. This agility allows manufacturers to respond promptly to market demands and seasonal variations.

Data-Driven Insights:

Many modern filling machines are equipped with data monitoring and analytics capabilities. This provides manufacturers with valuable insights into production efficiency, filling accuracy, and potential areas for improvement. Data-driven decision-making can lead to continuous optimization of the manufacturing process.

Compliance with Cleanroom Standards:

For hair oil products that require stringent cleanliness standards, Hair Oil Bottle Filling Machines can be designed to meet cleanroom requirements. This ensures that the production environment remains free from contaminants, meeting the high standards expected in the cosmetic industry.

Improved Shelf Life and Product Integrity:

The precision in filling ensures that each bottle contains the correct formulation, contributing to the overall quality and shelf life of the product. This is particularly crucial for hair oil products that may be sensitive to exposure or environmental factors.

Conclusion

The advent of Hair Oil Bottle Filling Machines represents a significant leap forward in the cosmetic and personal care industry. Offering precision, speed, and efficiency, these machines are not just tools for production but strategic investments for manufacturers looking to thrive in a competitive market. As technology continues to advance, embracing innovations like automated filling machines becomes paramount for businesses aiming to stay ahead in the evolving landscape of product manufacturing.

Want to know more about Hair Oil Bottle Filling Machine? – Connect with our experts now or write us at [email protected]

What Manufacturers in the Edible-Oil Industry Must Consider When Upgrading Their Packing Line?

Upgrading the packing line doesn’t mean getting newer machine…

How Do Temperature-Sensitive Oils Require Specially Designed Filling Equipment?

Temperature-sensitive oils—such as coconut oil, shea butter oil, certain medicinal oils, and some industrial-grade..

How Are Energy Sector Companies Benefiting from Bulk Lube Oil Filling Solutions?

The energy sector, spanning oil and gas, power generation, and renewable energy, is one of the most crucial industries globally..